- Home

- Products

- Application

Airport Fence icon

Airport Fence

School Fence iconSchool Fence

Sports Fence iconSports Fence

Residential Fence iconResidential Fence

Park & Garden Fence iconPark & Garden Fence

Industrial Fence iconIndustrial Fence

Partition Fence iconPartition Fence

Power Fence iconPower Fence

Oil & Gas Field Fence iconOil & Gas Field Fence

Railway Fence iconRailway Fence

Military Fence iconMilitary Fence

Prison Fence iconPrison Fence

Agricultural Fence iconAgricultural Fence

Construction Fence iconConstruction Fence

Crowd Barrier iconCrowd Barrier

- Service

- About Us

- Contact Us

- Home

- About Us

- Products

- Application

- Service

- Order Information

- Installation & Maintenance

- FAQs

- Catalog

- Video

- Drawings

- News

- 358 Security Fence – High-Security Perimeter Protection

- Anti-climbing metal fence - the best choice for safety and protection

- Choosing the Right Farm Fence: Protecting Livestock, Crops, and Property

- Secure Your Home with High-Quality Residential Fencing

- Galvanized Wire: The Durable and Versatile Solution for Various Applications

- Iron fence: exquisite interpretation of customized art and security protection

- Iron fence: perfect integration of craftsmanship and safety protection

- Choosing the right type of airport fence

- What factors affect the price of garden fences?

- Wrought iron fence craft

- 358 Fence: A Guide to Selecting a High-Security Fence System

- Maintenance and development trend of welded mesh fence

- Airport metal fence, a fence system used for security protection around the airport.

- Double Wire Fence: A Simple and Practical Fence Choice

- Rugged, durable and versatile BRC fence: the perfect choice for safety and practicality

- 358 anti-climb fence: a solid barrier for modern security

- Hexagonal mesh: Eco-friendly, protecting the beauty of nature

- Steel Fence: Durable and Secure Fencing Solutio

- Security guards for commercial places - Fence solutions

- Farm fences made of metal play an important role in agricultural production.

- Protection and Durability: Versatile Applications of Galvanized Wire

- Welded Mesh Fence: A Strong and Durable Security Choice

- Metal Fences: The Perfect Choice for Protection and Security

- Fence experts help you choose the right design and specifications for your steel picket fence panel

- Enhancing Privacy and Aesthetics: The Role of Garden Fences

- Industrial Fencing: Enhancing Security and Efficiency in Industrial Environments

- Welded wire mesh - a sturdy and durable safety net

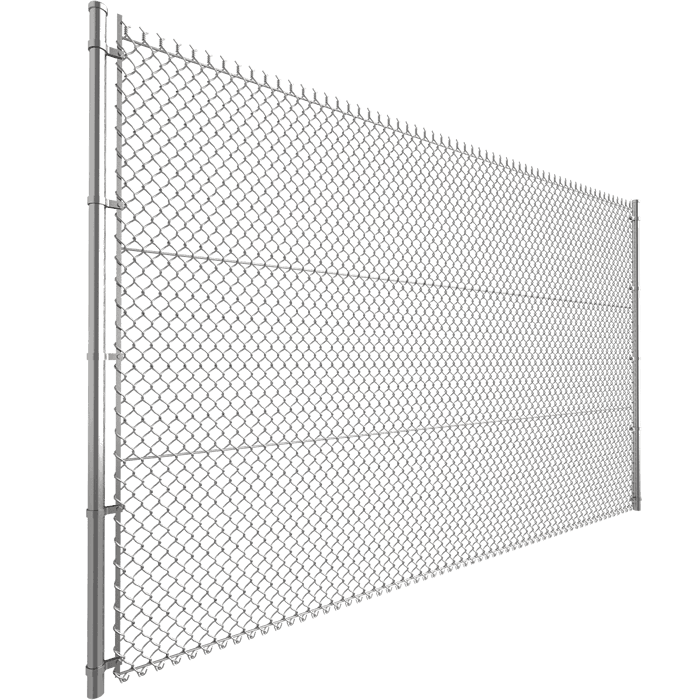

- Chain link fence – the guardian of your home

- Elegant and sophisticated metal garden security fence to protect your private oasis

- Garden metal fence

- High quality fencing system, brc fence

- The double wire fence, 656 wire fence or 868 wire fence

- 358 Security Fence introduction of safety fence

- 358 High Security Fence provides maximum safety and protection.

- A type of security fence designed specifically for use in parks and gardens

- sports fence, sports field fence

- Pros Share: How We Choose the Best Cyclone Fence Materials

- Looking at the future development trend of Cyclone Fence from a professional perspective

- welded mesh fence for Sports Facilities: Balancing Safety and Spectator Experience

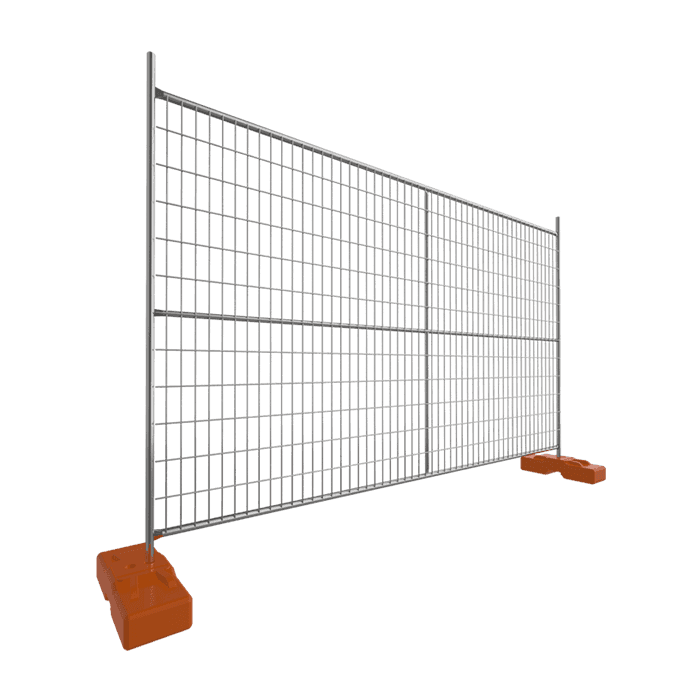

- Australia temporary fence: What You Need to Know

- Minimizing Environmental Impact: Sustainable Materials for Canada temporary fence

- A Essential for Professionals: A Troubleshooting Guide for Cyclone Fence

- Enhancing Security in Gated Communities: The Benefits of welded mesh fence

- welded mesh fence: A Stylish and Secure Option for Residential Developments

- Australia temporary fence vs. Chain Link Fences: Comparing Design and Functionality

- Canada temporary fence Rental for Canadian Music Festivals and Cultural Events

- Cyclone Fence aesthetics and functional design from a professional perspective

- Australia temporary fence: The Benefits of Using It

- Cyclone Fence: A Comprehensive Guide from Design to Installation

- Enhancing Security in Gated Communities: The Benefits of welded mesh fence

- Enhancing Safety and Security: The Role of Canada temporary fence in Event Management

- Canada temporary fence Solutions for Outdoor Retail Events and Trade Shows

- Australia temporary fence: A Versatile Option for Your Home

- In-depth analysis of Cyclone Fence materials and structure

- Enhancing Security in Public Parks: The Role of welded mesh fence

- Designing welded mesh fence Systems for Pedestrian Safety in Urban Areas

- Enhancing Security in Transportation Infrastructure: The Role of welded mesh fence

- welded mesh fence: A Cost-Effective Solution for Industrial Facilities

- Professional analysis of the structure and building process of Cyclone Fence

- Australia temporary fence: Easy and Quick to Remove

- Canada temporary fence Solutions fo Parks and Recreation Areas

- Exploring the Fire Safety Features of Canada temporary fence in Temporary Structures

- Comparing Australia temporary fence with Permanent Fences

- Choose and design a Cyclone Fence to suit your environment

- welded mesh fence: Enhancing Security in High-Traffic Areas

- Professional Guidance: Best Practices for Cyclone Fence

- Wire Fence Innovations: Advancements in 656 and 868 wire fence Technology

- Designing Prison Mesh Fencing for Optimal Surveillance and Monitoring

- The Importance of Geotextile Filters in Woven Gabion Baskets Applications

- Intrusion Detection Systems for Fence for airport: Technologies and Integration

- 358 security fence: Case Studies of Successful Implementations

- Comparing Installation and Maintenance of 656 and 868 Wire Fence Systems

- Prison Mesh Fencing: Minimizing False Alarms and Enhancing Response Times

- Woven Gabion Baskets for Earthquake-Resistant Construction: Lessons from Seismic Events

- Emergency Planning for Fence for airport: Evacuation and Contingency Measures

- The Evolution of 358 security fence: From Traditional to High-Tech Solutions

- 656 Wire Fence: A Versatile Option for Residential Gardens and Landscaping

- Prison Mesh Fencing: Addressing Challenges in Urban Environments

- Construction Considerations for Woven Gabion Baskets Retaining Walls on Soft Soils

- Fence for airport Perimeter Design for Unmanned Aerial Vehicle (UAV) Security

- 358 security fence: A Comprehensive Guide to Installation and Maintenance

- Understanding the Corrosion Resistance of 868 Wire Fence for Outdoor Applications

- Addressing the Challenges of Prison Mesh Fencing in Harsh Weather Conditions

- Hydraulic Performance of Woven Gabion Baskets in River Training Works

- Fence for airport Corrosion Protection: Coatings and Maintenance Strategies

- 358 security fence: Strategies for Addressing Vulnerabilities and Weak Points

- 656 wire fence: A Reliable Barrier for Wildlife Conservation Areas

- The Psychology of Deterrence: Understanding the Visual Impact of Prison Mesh Fencing

- Understanding the Structural Performance of Woven Gabion Baskets

- Fence for airport Systems: An Overview of Types and Features

- 358 security fence: Case Studies of Successful Implementations

- 656 Wire Fence: An Effective Solution for Temporary Storage Yards

- Prison Mesh Fencing: Addressing Challenges in Urban Environments

- Innovations in Manufacturing Woven Gabion Baskets: Improved Efficiency and Quality

- Fence for airport Testing and Certification: Ensuring Compliance with Industry Standards

- Incorporating Green Design Principles in 358 security fence

- The Legal and Ethical Considerations of 358 security fence

- Fence for airport: Key Factors in Perimeter Protection

- Evaluating the Hydraulic Conductivity of Woven Gabion Baskets Systems

- Prison Mesh Fencing: Effectiveness in Preventing Escape Attempts

- Enhancing Privacy and Safety with 868 Wire Fence

- The Role of Landscape Architecture in Integrating 358 security fence

- Fence for airport Maintenance: Strategies for Ensuring Long-Term Security

- Environmental Benefits of Woven Gabion Baskets in Restoration Projects

- The Role of Technology Integration in Modern Prison Mesh Fencing

- Enhancing Security in Gated Communities: The Role of 656 Wire Fence

- Exploring the Strength and Durability of 868 Wire Fence for Perimeter Protection

- Exploring the Different Types of Prison Mesh Fencing

- Hydraulic and Environmental Benefits of Woven Gabion Baskets Systems

- Ensuring Compliance and Effectiveness: Fence for airport Height Regulations and Standards

- The Impact of 358 security fence on Facility Design and Layout

- Comparative Analysis of 656 /868 wire fence: Strength, Rigidity, and Intrusion Prevention

- Innovations in Prison Mesh Fencing: Advancements in Security Technology

- The Role of Woven Gabion Baskets in Stormwater Management and Detention Systems

- Fence for airport Incident Management: Protocols for Intrusion and Breach Response

- 358 security fence: Mitigating the Risks of External Threats

- Enhancing Security in Transportation Infrastructure: The Role of 656 /868 wire fence

- Prison Mesh Fencing: Considering Privacy Concerns and Inmate Rights

- Woven Gabion Baskets in Mining and Quarrying Operations: Geotechnical Applications

- Fence for airport Material Selection: Balancing Strength and Durability

- 358 security fence: Mitigating the Risks of External Threats

- Design 656 /868 wire fence: A Homeowner’s Guide

- How to improve the reliability and safety of Prison Mesh Fencing?

- Things to note when designing Woven Gabion Baskets

- Construction safety and environmental protection measures for Fence for airport

- 358 security fence materials and manufacturing processes

- 656 /868 wire fence strength and durability assessment

- Application of Prison Mesh Fencing design

- The role of Woven Gabion Baskets in water resources management

- Safety evaluation and risk assessment of Fence for airport

- Woven Gabion Baskets Weaving: Making Tutorial

- Fence for airport material and structural requirements

- Fence for airport exterior design and landscaping

- Making Woven Gabion Baskets for decorative purposes

- What is a Prison Mesh Fencing?

- 656 /868 wire fence Purchasing Guide

- Measuring Woven Gabion Baskets

- Maintenance and maintenance methods of Fence for airport

- Materials and tools for Woven Gabion Baskets

- How to evaluate and improve the performance of Prison Mesh Fencing

- of 656 /868 wire fence on Property Value

- Quality control and safety assurance of Fence for airport

- Fence for airport construction period and progress control

- Application of Woven Gabion Baskets in civil engineering

- Security and Privacy with 656 /868 wire fence

- Future Development and Innovation of Prison Mesh Fencing

- Woven Gabion Baskets Fabrication: A Guide

- Future development trend and new technology application of Fence for airport

- Using Woven Gabion Baskets for Landscape Design

- Prison Mesh Fencing Cost and Budget

- Economics of using 656 /868 wire fence

- Installing 656 /868 wire fence: A Step-by-Step Guide

- Cases and successful cases of Prison Mesh Fencing

- Understanding the Different Types of Woven Gabion Baskets

- Construction technology and quality control of Fence for airport

- Cost and Budget Control of Fence for airport

- Fence selection guide: understand the characteristics of 656 /868 wire fence

- The importance of Prison Mesh Fencing is anti-climbing function

- Slope Stabilization Techniques: Utilizing Woven Gabion Baskets

- Types and characteristics of fence for airport systems

- Innovation of Woven Gabion Baskets Manufacturing Technology

- Understanding the Difference: 656 Wire Fence vs. 868 Wire Fence

- The Role of Prison Mesh Fencing in Modern Correctional Facilities

- Designing Effective Woven Gabion Baskets Retaining Walls

- Long-Term Security: Maintenance Strategies for fence for airport

- Meeting Industry Standards: Testing and Certification of fence for airport

- Unique Design Wrought Iron Fence: Dream Garden Gate

- Steel Picket Fence: not just a fence-but also a garden decoration

- Revolutionizing abutments: the power of Welded Gabion

- Welded Gabion sound insulation walls: aesthetic and functional sound insulation

- Chain link fence - - NIGERIA

- Steel Picket Fence safety performance evaluation report

- Maintaining Order in Public Places: The Benefits of crowd control pane

- The Science of crowd control pane: Understanding the Impact of Control Panels

- Welded Gabion: Aesthetic and Functional Boundary Solutions

- Deer fence - - Malaysia

- Wrought Iron Fence VS Steel Picket Fence: Which Is Right For You

- Welded Gabion: A Robust Solution for Soil Protection and Bank Stabilization

- Legal framework for the use of crowd control pane: rights, regulations and responsibilities

- Application and Performance Evaluation of Welded Gabion in Water and Soil Conservation Engineering

- Cattle Panel Fence - - Canada

- Wrought Iron Fence laboratory testing and certification standards

- Safety protection measures for Steel Picket Fence

- Durability and Corrosion Resistance of Welded Gabion Materials: Testing and Evaluation

- Welded gabion specifications: to ensure the safety of engineering projects

- Welded wire mesh fence - - Maldives

- See defense techniques for wrought iron fences

- Wind resistance performance test results of Steel Picket Fence

- crowd control pane Olympics: Battle for Order Gold

- stunning illusions that transform objects into Welded Gabion

- Welded wire mesh fence - - Lesotho

- Material characteristics and selection of Wrought Iron Fence

- The relationship between the color selection of Steel Picket Fence and architectural style

- Evaluating the Effectiveness of Welded Gabion: Indicators and Performance Analysis

- crowd control pane Design: Optimizing for Functionality

- crowd control pane: Ethical Considerations and Privacy Protections

- The relationship between Wrought Iron Fence and environmental protection

- Steel Picket Fence safety performance testing and certification

- Welded Gabion and Ecological Restoration: Creating Stable Habitats Through Environmental Engineering

- crowd control pane Experiment: Going Through Obstacle Courses

- Fire performance of Welded Gabion materials: ensuring safety in high-risk areas

- How to spray the Wrought Iron Fence

- How to Install a Gate on a Steel Picket Fence

- Welded Gabion standard: to ensure the quality of engineering projects

- crowd control pane Technologies: The Role of Physical Barriers and Signage

- crowd control pane and Public Protests: Balancing Security and Free Speech

- Check Out These Interesting Wrought Iron Fence Looks

- Steel Picket Fence construction procedures and specifications

- Anti-corrosion measures for Welded Gabion mesh: ensure service life

- Music Festival crowd control pane: Ensuring a Safe, Enjoyable Experience

- Welded Gabion Specifications: Ensuring Project Safety

- Installation skills of Wrought Iron Fence

- Create your own private garden with a Steel Picket Fence

- Application and Performance Research of Welded Gabion in Embankment Engineering

- crowd control pane in stadiums: Ensuring a smooth flow of spectators

- Assessing the Effectiveness of Crowd Control Pane Systems: Indicators and Measurement Techniques

- How to install the Wrought Iron Fence correctly

- How to choose the Steel Picket Fence material that suits you

- Understanding the Mechanics of Welded Gabion Stability

- crowd control pane Techniques: Dispersion, Containment and De-escalation Strategies

- Understanding the Mechanics of Welded Gabion Structural Design

- Anti-corrosion treatment technology and method of Wrought Iron Fence

- Dimension measurement and calculation method of Steel Picket Fence

- Bearing Capacity and Seismic Analysis of Welded Gabion Mesh

- crowd control pane Systems: Integrating Technology for Efficiency

- The Evolution of crowd control pane: From Megaphones to Laser Beams

- Wrought Iron Fence Material Strength Test Results

- Strange Applications for Steel Picket Fence: Incredible Ideas

- Application of Welded Gabion in Environmental Restoration: River Bank Restoration and Land Stabiliza

- The Role of a Crowd Control Panel Operator: Training and Responsibilities

- Welded Gabion Monitoring and Alarm System: Real-Time Detection and Response

- Iron master - Wrought Iron Fence

- Steel Picket Fence Care and Maintenance Guide

- Environmental Impact Assessment and Sustainability Considerations for Welded Gabion

- crowd control pane: An Overview of Tools and Techniques

- Evaluating the Effectiveness of crowd control pane: Indicators and Measurement Techniques

- Details to pay attention to when installing Wrought Iron Fence

- Check Out These Interesting Steel Picket Fence Designs

- Anatomy of Welded Gabion Mesh: Component Technology

- Crowd control pane Technology: Innovations to Enhance Crowd Management

- Anatomy of a Welded Gabion: Connection and Assembly Techniques

- Environmental Index Evaluation of Wrought Iron Fence

- Steel Picket Fence service life test results

- Gabion Wars: Welded Gabion vs Woven Gabion

- Risk Assessment and crowd control pane Deployment: Mitigating Potential Hazards

- Airport crowd control pane: Ensuring Smooth and Safe Passenger Flow

- Safety Performance Evaluation of Wrought Iron Fence

- Steel Picket Fence: Not just Protection, but Decoration

- Welded Gabion for Coastal Defense: Effective Measures to Protect Against Erosion

- Water Permeability and Hydraulic Performance of Welded Gabion Structures

- The Science behind crowd control pane: Understanding Crowd Behavior

- How to choose the Wrought Iron Fence accessories that suit you

- Steel Picket Fence:How safe is Steel Picket Fence

- Evaluating the Effectiveness of Welded Gabion: Metrics and Performance Analysis

- crowd control pane: A Comprehensive Guide to Managing Large Gatherings

- crowd control pane in Emergency Situations: Coordinating Response Efforts

- The Importance of Wrought Iron Fence Color to the Exterior of Your Home

- The relationship between price and quality of Steel Picket Fence

- Impact Resistance of Welded Gabion Structures: Testing and Certification Standards

- crowd control pane Case Studies: Real-Life Success Stories in Event Management

- The Role of Welded Gabion in Erosion Control: Effective Measures for Soil Stabilization

- technical analysis of Wrought Iron Fence anticorrosion treatment

- design principle and process of Steel Picket Fence

- Welded Gabion: The Key to Building Strong and Durable Retaining Walls

- Ensuring Public Safety with crowd control pane: Best Practices and Guidelines

- crowd control pane Rentals: A Cost-Effective Solution for Temporary Events

- Wrought Iron Fence: The ideal fencing solution for high security applications

- Steel Picket Fence vs. Other High Security Fencing Materials: Why Steel Picket Fence Is The Best Cho

- Welded Gabion: Best choice for retaining walls in high traffic areas

- crowd control pane: Keep Events Organized and Safe

- Evaluating crowd control pane Manufacturers: Choosing the Best Supplier for Your Event

- Steel Picket Fence: The Perfect Combination of Style and Security for Residential Fencing

- The Benefits of Using Wrought Iron Fence for Privacy and Aesthetics

- Welded Gabion Baskets: The Secret to Natural Garden Retaining Walls

- crowd control pane Deployment Strategies: Ensuring Smooth Event Flow

- crowd control pane Maintenance: Ensuring Longevity and Performance

- Guidelines for Construction of Welded Gabion

- The role of crowd control pane in event safety: a critical analysis

- Welded vs Braided Gabions: Which Is Better

- Steel Picket Fence: The Ultimate Fence for Infrastructure

- Advantages of Wrought Iron Fence in Border Security

- crowd control pane Material: Balanced Durability and Aesthetics

- Welded Gabion - Environmentally Friendly Flood Control Solution

- Welded Gabion - Versatile Choice for Outdoor Decoration

- Steel Picket Fence & Compliance: Meets Industry Standards

- Benefits of Using Wrought Iron Fence for Residential, Commercial and Industrial Fencing

- Customizing Your Wrought Iron Fence: AddingCoating Options

- Customer Testimonials: Real-Life Stories of Steel Picket Fence Success

- Welded Gabion: A Sustainable Solution for Coastal Protection

- The Psychology of crowd control pane: How Panels Influence Crowd Behavior

- crowd control pane Innovations: The Future of Event Crowd Management

- The Advantages of Using 358 security fence for High-Security Applications

- Welded Gabion Baskets: The Perfect Material for Sustainable Architecture

- The Importance of crowd control panel in Large Gatherings

- Cattle fence Tensioning Systems: Ensuring Proper Fence Integrity

- Customer spotlight: How wrought iron fencing improves security at government facilities

- The Science Behind Woven Gabion Baskets Strength and Durability

- Welded Gabion: The Key to Building Long-Lasting Retaining Walls

- Customizing Your Double Wire Fencing: Adding Height Options

- The Benefits of Temporary Fence for Construction Sites

- DIY Farm Fencing: A Step-by-Step Guide for Hands-On Property Owners

- Welded Mesh Fence Panel vs. Chain Link Fence: Which Offers the Best Strength and Durability

- 358 Mesh Fence: Unyielding Protection - Customer Satisfaction and Performance Revealed

- Chain Link Mesh: Beyond Boundaries - Unlocking the Potential of Secure Installations

- Double Wire Fencing: The Ultimate Defense - Effectiveness and Long-Term Maintenance Explained

- 358 Mesh Fence in Transportation Design: Creating Safe and Secure Transit Stations

- Welded Mesh Fence Panel: Uniting Strength and Style - A Comprehensive Product Review

- 358 Mesh Fence: Fortifying Security to the Highest Level - Showcasing Effectiveness and Client Satis

- Double Wire Fencing: Double the Security, Double the Confidence - Features and Installation Guide

- Chain Link Mesh: Versatile and Reliable - Enhancing Security with Ease of Maintenance

- 358 Mesh Fence: Beyond Expectations - A Customer-Centric Approach to Quality and Performance

- Why 358 mesh fence Are a Top Choice for High-Security Applications

- Maximizing Style and Functionality with Chain link mesh Designs

- 3d wire mesh fence Design Ideas for Residential and Commercial Properties

- Understanding the Materials Used in double wire fencing

- Chain link mesh: Taming Wild Nature for Ecological Conservation

- Historic Landmarks and Chain link mesh

- Positive Feedback on Double Wire Mesh Fence Installation

- 3d wire mesh fence Maintenance: How To Keep Your Fence In Top Condition

- Guardians of the Green: Chain link mesh for Arboretums

- Explore Innovations in 358 mesh fence

- Rust Resistant 358 mesh fence - Keeps Its Original Look

- Rustless 3d wire mesh fence: The Secret to Beauty and Longevity

- Ways to keep the double wire fence beautiful - the advantages of anti-rust

- Prevent Rust on double wire fencing

- Cleaning and maintaining the Chain link mesh - keeping its luster

- double wire fencing: The Unbreakable Fortress of Fanciful Filigree

- Exploring the Dynamic Applications of 3d wire mesh fence in Public Spaces

- Comparing 358 mesh fence to Other Common Security Fencing Options

- Chain link mesh: More Than Meets the Eye

- The Zen of Gardening: Creating Serene Spaces with Chain link mesh

- 358 mesh fence for Schools and Public Buildings: Safety and Security

- 3d wire mesh fence for Parks and Public Spaces: Beauty and Safety in One

- The Versatility of Chain link mesh: Unlocking Its Creative Potential

- double wire fencing: Protecting Residential Properties With Modern Style

- Breaking Down Barriers: How Chain link mesh Are Changing the Urban Landscape

- Enhancing Security with 3d wire mesh fence: A Three-Dimensional Fortress

- Securing Industrial Sites with 358 mesh fence Systems

- Breaking the Stereotype: Chain link mesh as a Fashion Statement

- Choosing the Right Height and Gauge for Your double wire fencing

- Chasing Shadows: The Art of Photography through Chain link mesh

- Unleashing the Beast: Extreme Sports and Chain link mesh

- The Advantages of double wire fencing for Commercial and Industrial Properties

- Unraveling the Strength: The Surprising History of Chain link mesh

- Installation Tips for 3d wire mesh fence: A Step-by-Step Guide

- Understanding the Versatility of 358 mesh fence Accessories

- The Ultimate Guide to 3d wire mesh fence: Benefits, Applications, and Durability

- Exploring the Durability and Strength of double wire fencing

- The Durability and Longevity of Chain link mesh

- The Aesthetic Appeal of Chain link mesh: Creative Design Options for Your Property

- Examining the Maintenance Requirements of 358 mesh fence

- Double Wire Fencing vs. Traditional Fencing: A Comparative Analysis

- The Environmental Benefits of Chain Link Mesh as a Sustainable Fencing Option

- The Role of Chain Link Mesh in Animal Enclosures and Kennels

- Exploring the Advantages of 3D Wire Mesh Fence for Residential Boundaries

- Safeguarding Perimeter Areas: Benefits of 358 mesh fence

- Exploring Galvanized and Vinyl-Coated Chain Link Mesh Options

- Exploring the Advancements in 358 Mesh Fence Technology for Enhanced Perimeter Protection

- Enhancing Privacy and Aesthetics with 3D Wire Mesh Fence Systems

- Addressing Security Concerns with Double Wire Fencing in Industrial Areas

- Addressing Security Needs with Chain Link Mesh in Commercial Settings

- Case Study: 3D Wire Mesh Fence in Urban Landscaping Projects

- The Advantages of 358 mesh fence for High-Security Areas

- Incorporating Privacy Slats with Chain link mesh

- double wire fencing is the Perfect Choice for Your Property

- Why Chain link mesh is the Best Choice for High-Security Facilities

- Exploring the Strength and Security of 358 Mesh Fence

- 3D Wire Mesh Fence: Adding Dimension and Style to Perimeter Protection

- Exploring Different Weave Patterns in Chain Link Mesh

- Maintaining and Repairing Double Wire Fencing: Best Practices

- Choosing the Right Gauge and Height for Your Chain Link Mesh Fence

- Comparing 358 Mesh Fence to Other Types of Security Fencing

- 3d wire mesh fence: innovative design and excellent performance

- double wire fencing: A Strong and Durable Fencing Solution

- Chain link mesh vs Double Wire Fencing: A Comparison of Two Affordable Fencing Solutions

- Chain link mesh: An Affordable and Easy-to-Install Option

- 358 Mesh Fencing for Schools and Public Buildings: Ensuring Safety and Security with a Touch of Inno

- Embrace the Futuristic Vibes: How 3D Wire Mesh Fencing Transforms Your Property with Style and Funct

- Unlock the Secrets of Flawless 358 Mesh Fencing Installation: Master Tips and Techniques for a Proje

- Double the Fun: Mastering Double Wire Fencing Installation with Expert Tips and Techniques!

- Chain Link Mesh Fencing Installation Unleashed: Masterful Tips and Techniques for a Project That's O

- How does chain link mesh compare to other types of fencing in terms of durability?

- How does double wire fencing compare to other types of fencing in terms of cost?

- What are the maintenance requirements for High Security 358 Mesh Fence?

- Can 358 mesh fence be used for residential properties?

- What are the typical applications of 3D wire mesh fence?

- Installation Tips for Chain Link Mesh Fencing: A Step-by-Step Guide

- Transforming Spaces with 3D Wire Mesh Fence

- Installation Tips for Double Wire Fencing: A Step-by-Step Guide

- The Importance of Proper Installation Techniques for 358 Mesh Fence Performance Optimization

- Case Study: How 358 Mesh Fence Revolutionized Prison Security Systems

- Innovative Uses of 3D Wire Mesh Fence in Modern Architecture

- Understanding the Strength and Durability of BRC Mesh Fence for Industrial Security

- Australia Temporary Fence Regulations: Ensuring Safety and Compliance in Temporary Construction Site

- Unveiling the Superior Security Features of 358 Mesh Fence for High-Risk Facilities

- Advantages and Features of 358 Mesh Fence for Enhanced Security

- The Art of Versatility in 3D Wire Mesh Fence: Unlocking the Design Potential of 3D Wire Mesh Fence

- Australia Temporary Fence: Portable and Reliable Barrier for Public Safety

- BRC Mesh Fence: Exploring the Different Mesh Patterns in BRC Mesh Fence Design

- The Science Behind 358 Mesh Fence: A Detailed Analysis of Its Impenetrable Design

- Exploring the Applications of 358 Mesh Fence in Critical Infrastructure Protection

- 358 Mesh Fence: The Ultimate Choice for Enhanced Perimeter Protection

- 358 Mesh Fence: Unparalleled Security and Durability for Perimeter Protection

- BRC Mesh Fence: Reliable and Versatile Solution for Secure Enclosures

- 3D Wire Mesh Fence: Adding Dimension and Strength to Perimeter Security

- Australia Temporary Fence: Ensuring Safety and Flexibility in Temporary Environments

- 3D Wire Mesh Fence: Innovating Boundaries with the Versatility of 3D Wire Mesh Fence

- Australia Temporary Fence: Secure Your Site with the Reliability of Australia Temporary Fence

- BRC Mesh Fence: Combining Durability and Efficiency with BRC Mesh Fence

- 358 Mesh Fence: The Optimal Choice for High-Security Environments and Beyond

- 358 Mesh Fence: Unmatched Security and Strength for Perimeter Protection

- 3D Wire Mesh Fence: Add Depth and Style to Your Perimeter - Unleash the Potential of 3D Wire Mesh Fe

- Australia Temporary Fence: Versatile Solutions for Temporary Site Security - Explore Australia Tempo

- BRC Mesh Fence: Secure Your Property with Reliable and Versatile BRC Mesh Fence

- Double Wire Fencing: Enhance Security with Double the Strength - Discover Double Wire Fencing

- BRC Mesh Fence: The Ultimate Choice for High-Security Perimeters - Experience the Strength of BRC Me

- Australia Temporary Fence: Versatile Solutions for Temporary Site Security

- Double Wire Fencing: Double the Security, Double the Protection

- Discover the Dimensional Beauty of 3D Wire Mesh Fence for Modern Design

- Discover the Superior Quality of BRC Mesh Fence: Securing Your Property with Confidence

- BRC Mesh Fence: The Ultimate Choice for High-Security Perimeters

- 358 Mesh Fence vs. BRC Mesh Fence: Choosing the Right Security Solution for Your Needs

- Welded Mesh Fence Panels: A Practical Guide to Enhancing Security with Sturdy Fencing Solutions

- Unmatched Protection: The Trusted Choice of BRC Mesh Fence for Reliable Security Measures

- Securing with Strength: The Superiority of BRC Mesh Fence in Perimeter Protection

- Beyond Boundaries: Exploring the Versatility of BRC Mesh Fence in Various Applications

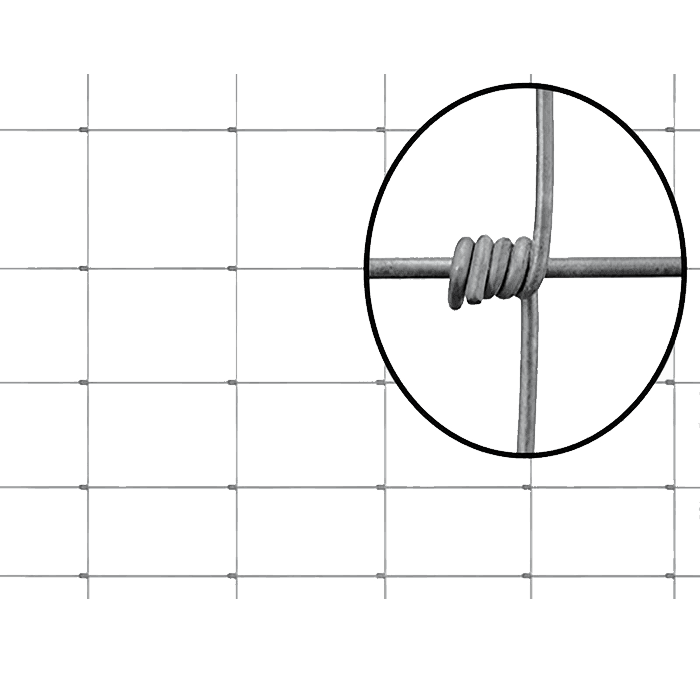

- Field Fence: Secure Your Property with Reliable and Durable Fencing Solutions

- BRC Mesh Fence: Elevate Security Standards with Premium Perimeter Protection

- BRC Mesh Fence: Uncompromising Strength and Style for Perimeter Protection

- Immerse Yourself in a 3D World of Security: Discover the Power of 3D Mesh Fence

- Versatile and Secure: Explore the Benefits of Welded Mesh Fence Panels

- Experience the Power of 3D Mesh Fence: Defending Your Space with Style and Strength

- 3D Wire Mesh Fences: Elevate Your Security Standards with Innovative Perimeter Defense

- Embrace the Future with 3D Wire Mesh Fence: Modern Design and Superior Security

- BRC Mesh Fence: Reinforce Your Boundaries with Trusted Perimeter Protection

- BRC Mesh Fence: Uncompromising Security and Durability for Your Property

- Protect Your Property and Safety: Choose BRC Mesh Fence!

- Metal Mesh Fencing: The Perfect Blend of Aesthetics and Practicality

- Welcome to Our Metal Fence Manufacturer!

- Metal Chain link fence has excellent durability, beauty, and safety

- High-Quality Chain link Fence Makes Your Public Place Safer and More Comfortable

- Factors to Consider When Choosing a Metal Fence System for Your Property

- This article will introduce the advantages of chain link fence from material characteristics, usage

- Showcasing Modern Aesthetics with Perfectly Crafted Welded Metal Fencing for Your Yard

- Benefits of Using Metal Crowd Control Barriers for Crowd Management:

- Garden fences are a popular and versatile type of fence

- One of the main advantages of crowd barricade fencing is its flexibility.

- This article will give you some tips on how to choose a fence for your farm.

- Wrought iron fence is a metal fence with a wide range of uses

- Build a temporary fence for your home or business

- High quality chain link fence, a durable and versatile fencing option

- Bending fence net is also called triangular bending fence net

- Straight razor wire is a new type of protective net

- How to distinguish the quality of wrought iron guardrail

- What are the universality of chain link fence

- Fence mesh with special production process

- Easy installation of farm fence

- Decorative Steel Fence to keep your home safe.

- Chain link fence installation

- Triangle wire mesh fence, wiremeshfence

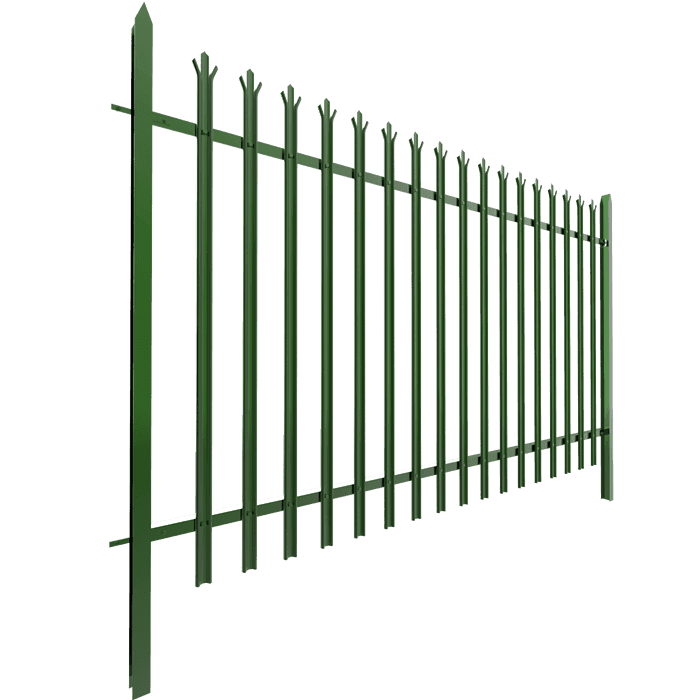

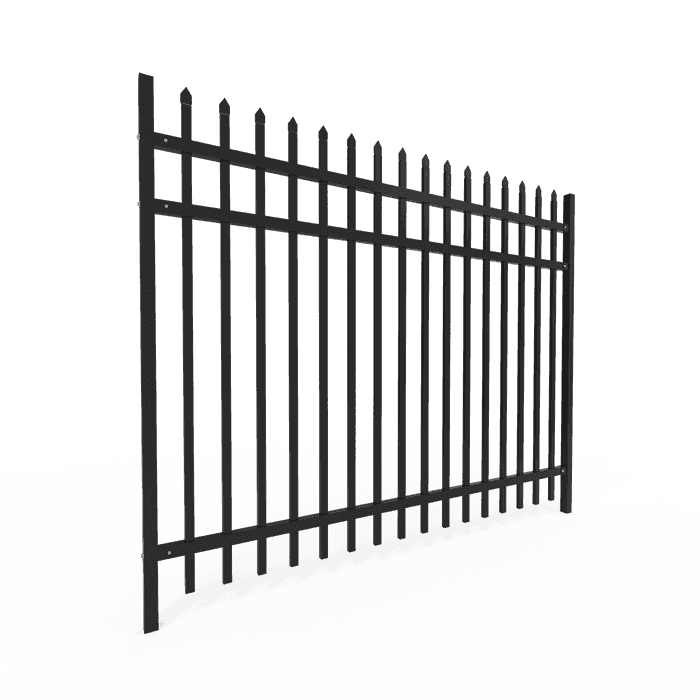

- Palisade fence - wiresfence

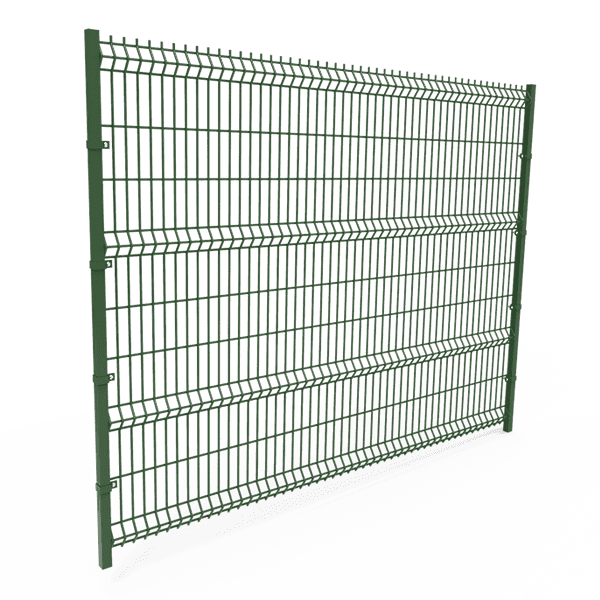

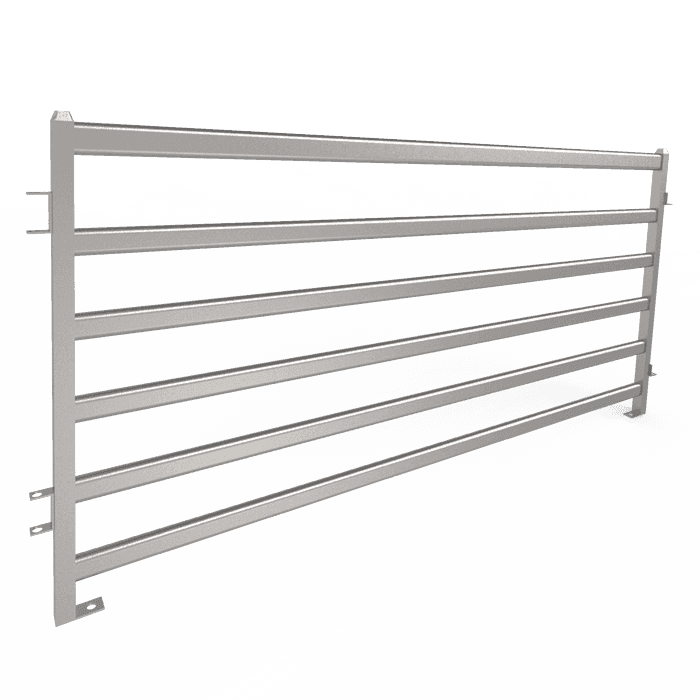

- Doule wire fence - wiresfence

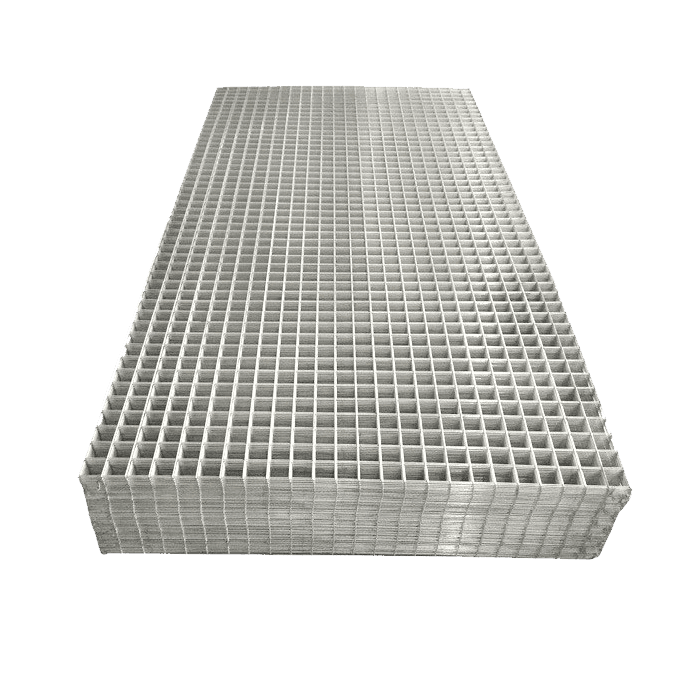

- Welding process requirements for electric welding steel mesh

- Contact Us

- Privacy Policy

- Terms & Conditions

jpg)

9.13wires.jpg)